|

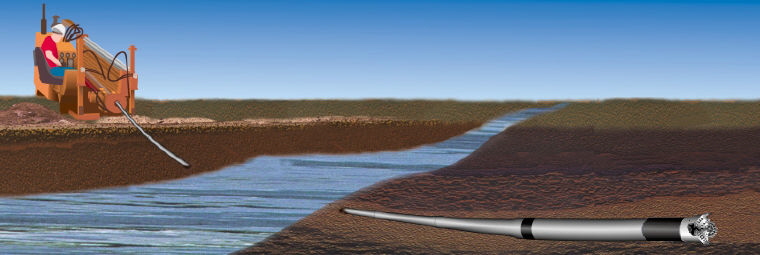

Drilex offers a full line of quality and reliable power section sizes. The power section is the part of a downhole motor or other tool that converts hydraulic energy from the operating fluid into mechanical rotational energy. The power section consist of two parts, the rotor and the stator.

The rotor is comprised of either a high carbon alloy or a stainless steel bar and is machined with a helical (multi-lobe) pattern. The rotor can be coated to reduce wear and corrosion.

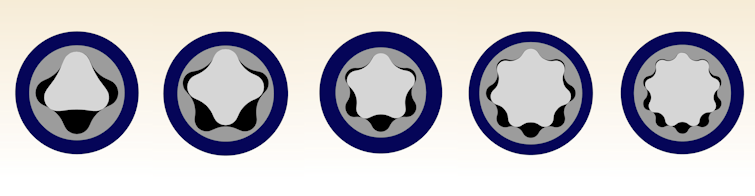

The stator is a length of tubular steel that is lined with an elastomer (rubber) compound. The elastomer is formed with a helical (multi-lobe) pattern similar to that of the rotor. The difference between the stator and the rotor is that the stator always has one more lobe than the rotor. For this reason, the ratio of rotor lobes (X) to the stator lobes (X+1) is designated as (X):(X+1). For example: 3:4, 5:6, 7:8, and 9:10. For more information about the Drilex rotors and stators, please click on the Features and Advantages tab.

The table above shows the available power sections, arranged by the outer diameter. Just click on the model number to view the PDF specification sheet. If you need further assistance or in need a power section that is not listed, please contact your nearest Drilex Representative or call our office directly.

|